feed and feasibility study

Developing a bespoke product forms a fundamental aspect of devising a solution, however, there are instances where project loads and/or pressures present an area of concern.

In this instance, design calculations and FEA can be conducted to theoretically verify a system design, using recognised industry standards in conjunction with client specifications.

From conceptualised design, we can provide a full report to support product realisation. The study will assess the conceptualised design in line with client provided data, industry data and applicable standards. We have worked to or in accordance with the following;

Design:

API17L1/2 Flexible ancillary equipment design

ASME VIII Div 2 Rules for Construction of pressure vessels

DNVGL-ST-0337 Standard for shipboard lifting appliances

DNVGL-RP-F113 Pipeline Subsea Repair

Material:

Norsok M-001 Materials selection

EN 10204 Metallic products

ISO 898 Standard specification for carbon steel nuts & bolts

NACE: MR-0175

Fabrication:

EN ISO 15614-1 Specification for Qualification of Weld Procedures

Norsok M-101 Structural Steel Fabrication

ASME IX Welding, Brazing & Fusing Qualifications

EEMUA 158 Construction Specification for Fixed Offshore Platforms

Protection:

Norsok M-501 Surface preparation & protective coating

DNV-RP-B401 Cathodic protection

Norsok M-503 Cathodic protection

With the correct standards identified, we can produce design calculations & finite element analysis (FEA), with more specialist techniques utilised where applicable.

The study can be complimented with a failure mode effect and criticality analysis (FMECA), third party design verification using the likes of Lloyds, DNV or BV or an alternative client preferred validation method. This would be controlled using our in-house project management expertise.

DESIGN calculations

A design report, inclusive of calculations, is compiled to provide mechanical analysis and theory for specific equipment. They are utilised to verify a products capacity to perform in operation when subjected to real-time conditions.

Calculations are typically conducted to recognised industry standards and include applicable levels of contingency, ensuring integrity in accordance with accidental load-cases or similar.

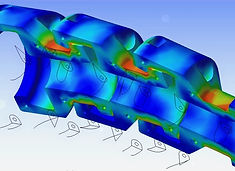

finite element analysis

Further to theoretical design validation by calculation, it is often worthwhile expanding upon to utilise simulation software to apply loads to a CAD model applying pessimistic project variables. This allows our engineering team to determine:

-

Design capabilities to withstand loadings

-

Identify areas of weakness or unnecessary strength

-

Areas in which could be adjusted to provide a more economical solution